ECO-FLEX 130

Flexible signage bollard

A self-righting reflective bollard with a 130 mm diameter, designed for signage and zoning in private sites, industrial areas, parking lots, or public spaces such as bike lanes and pedestrian paths. It ensures user protection while minimizing or eliminating damage to equipment.

High visibility is provided by its retro-reflective system, which includes three 3M reflective films compliant with EN12899-3 standards, as well as two rings of glass beads positioned at the top and base of the bollard, ensuring optimal visibility day and night.

Its flexible, memory-form structure offers high resistance and returns to its original shape after impact, significantly reducing maintenance costs.

Made from UV-protected polyurethane for maximum durability.

Customisation options are available to meet specific site needs—contact us for more details.

Anchoring base adapted to the type of support and site-specific constraints.

Applications

Certifications

TECHNICAL SPECIFICATIONS

Description

Flexible bollard with shape memory structure that automatically springs back into its original shape after an impact, without damaging the seal.

Protects users, particularly 2-wheelers, from head impacts compared to a steel post.

Dimensions

Diameter: 130 mm.

Height above ground: 800 mm.

Weight: 3,350 kg.

Aluminium anchoring foot: diameter 48 mm x height 150 mm.

Bollard colour

Black (RAL 9005).

Custom RAL available based on quantity.

Reflective elements

3 white reflective strips.

2 reflective glass beads rings for additional signage.

Other configurations on request.

Installation instructions

Core drill 60 mm in diameter x 160 mm deep minimum. Sealed with SIKADUR 30 or SIKADUR 42 epoxy adhesive.

Maintenance

Post screwed into its anchoring foot.

Simple temporary replacement or removal.

Applications

Delimiting private areas, industrial sites, car parks or public spaces.

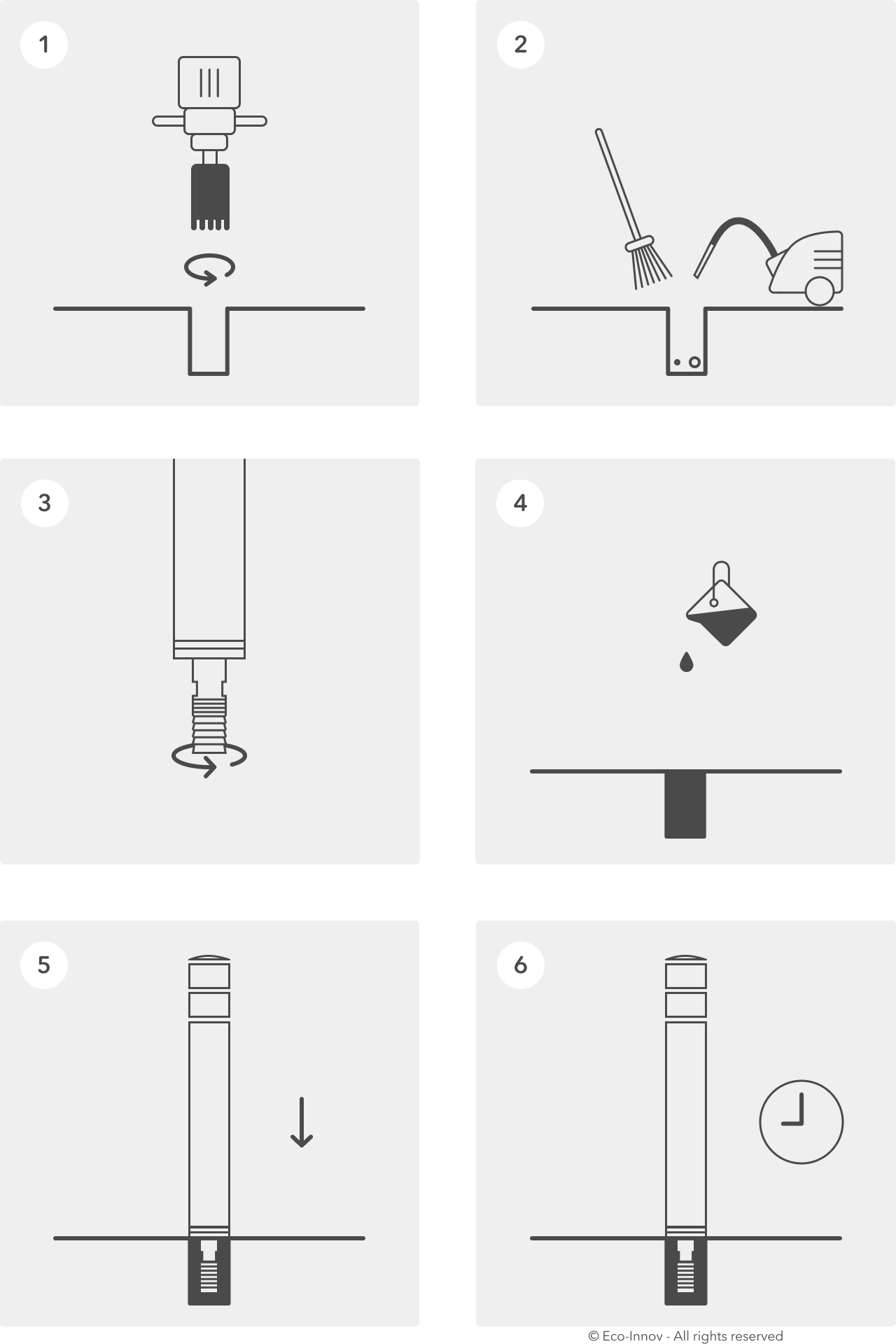

1. After spotting the bollards location, drill a hole 70 mm in diameter and 170 mm deep.

2. Carefully brush and clean the hole to remove any dust and traces of damp that would affect the efficiency of the adhesive.

3. Screw the anchor foot firmly under the post.

4. Pour the appropriate bonding adhesive into the hole about 2/3 of the way down. To assess the correct quantity of adhesive, make sure that it extends all the way to the bottom of the post without creating any extra thickness. We recommend using SIKADUR 30 or SIKADUR 42 two-component epoxy adhesive.

5. Insert the bollard into the hole filled with adhesive.

6. Allow the adhesive to dry before applying any mechanical stress and before re-establishing traffic (refer to the adhesive’s instructions for use).

_

Failure to follow these instructions may invalidate the warranty.