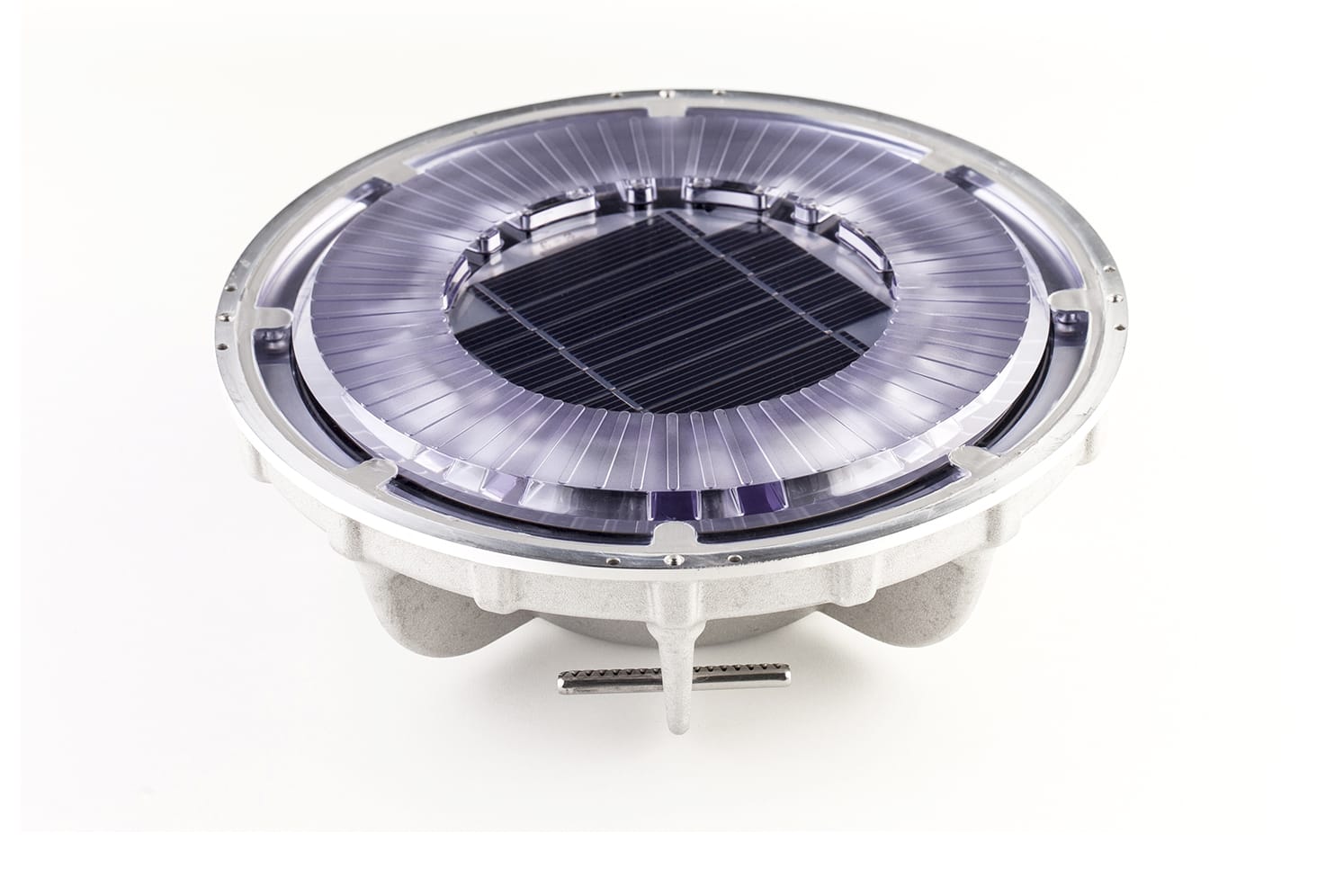

ECO-246

Road embedded solar stud

Fully self-contained luminous beaconing solution, suited to roads with regular heavy vehicle traffic. Used for 360º applications such as marking the edges of traffic islands and mini-roundabounts.

Applications

Resistance

Standards

LED Colors

Beaconing

24 LED, 360º, Blinking, Grazing

Certifications

TECHNICAL CHARACTERISTICS

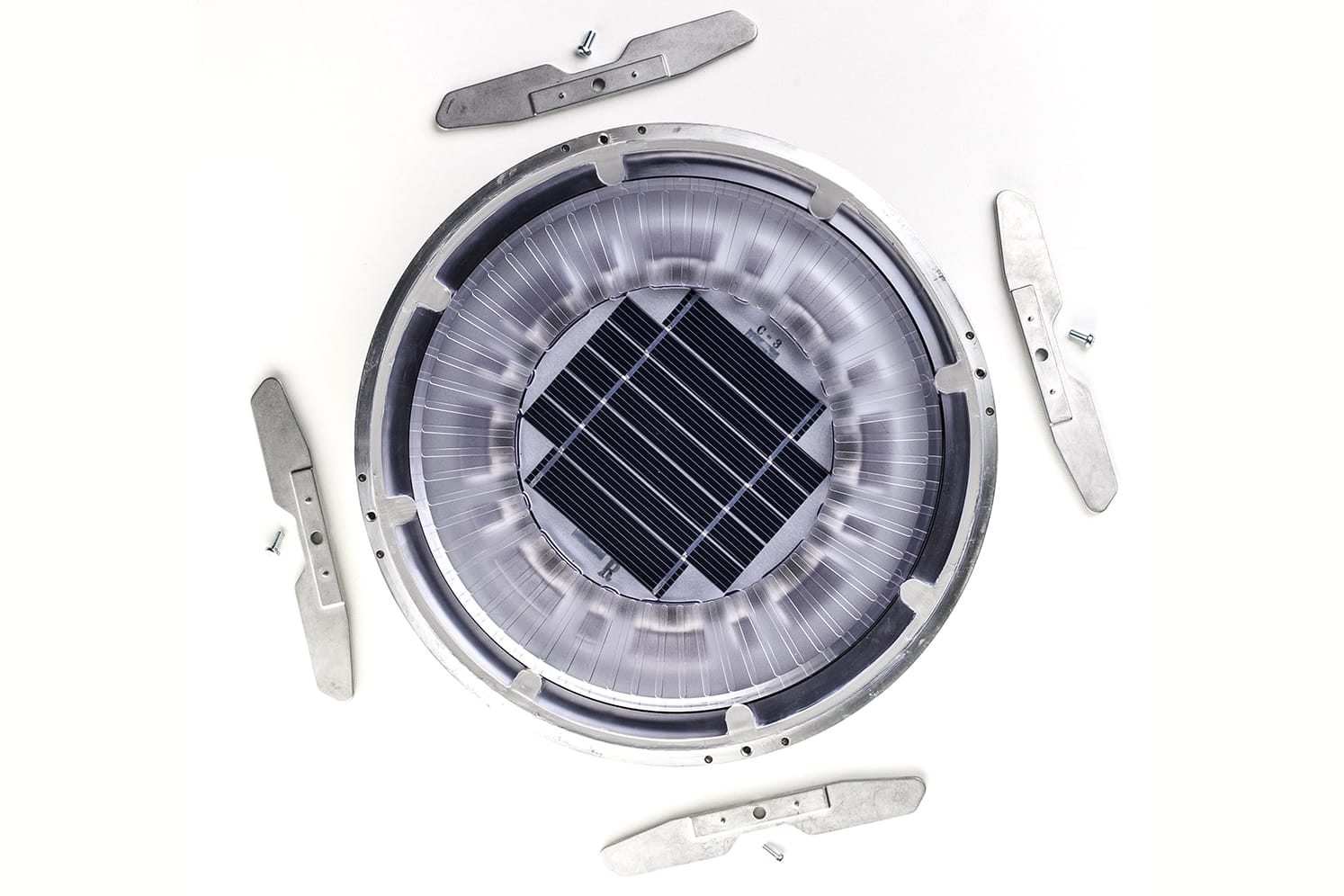

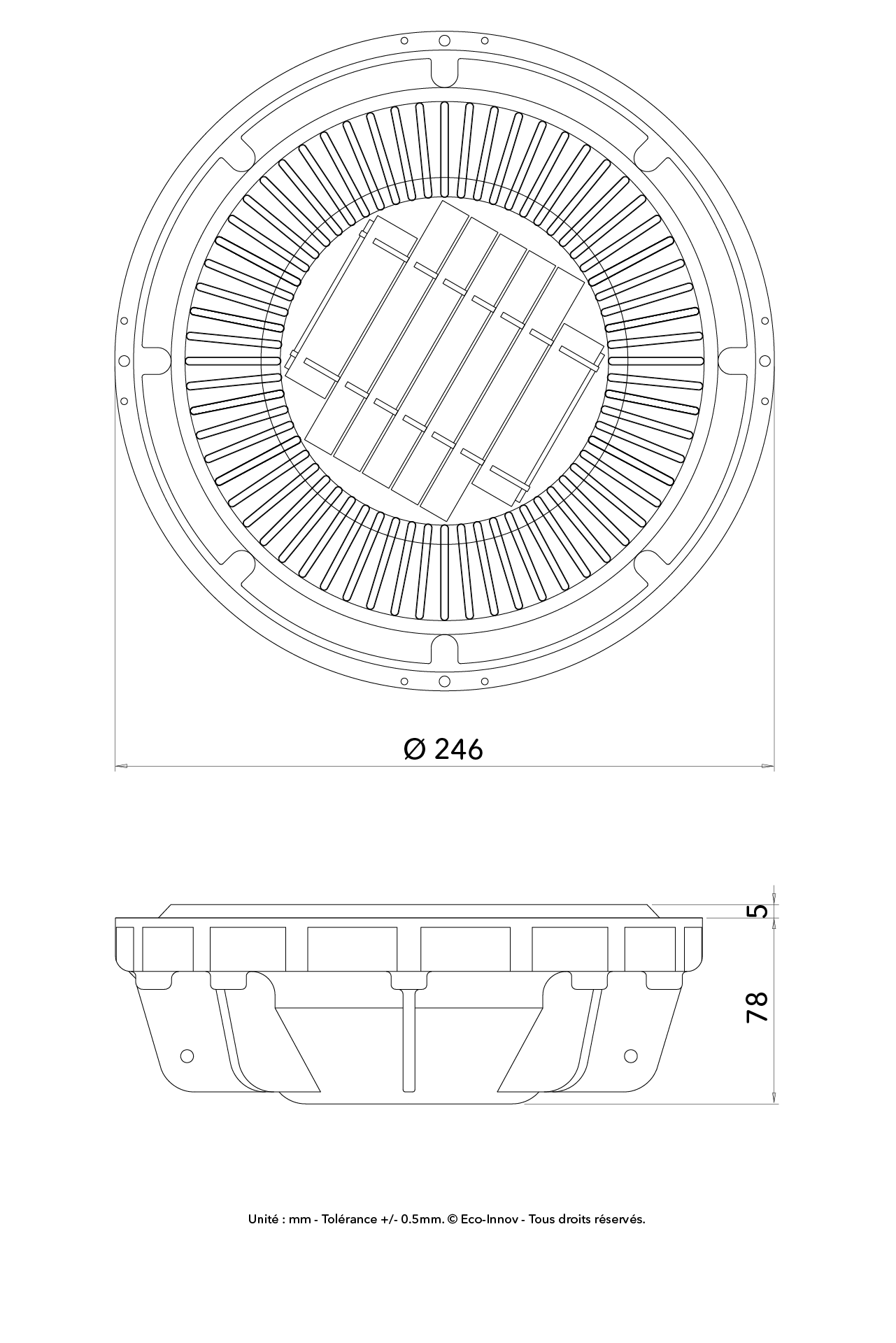

Dimensions and weight

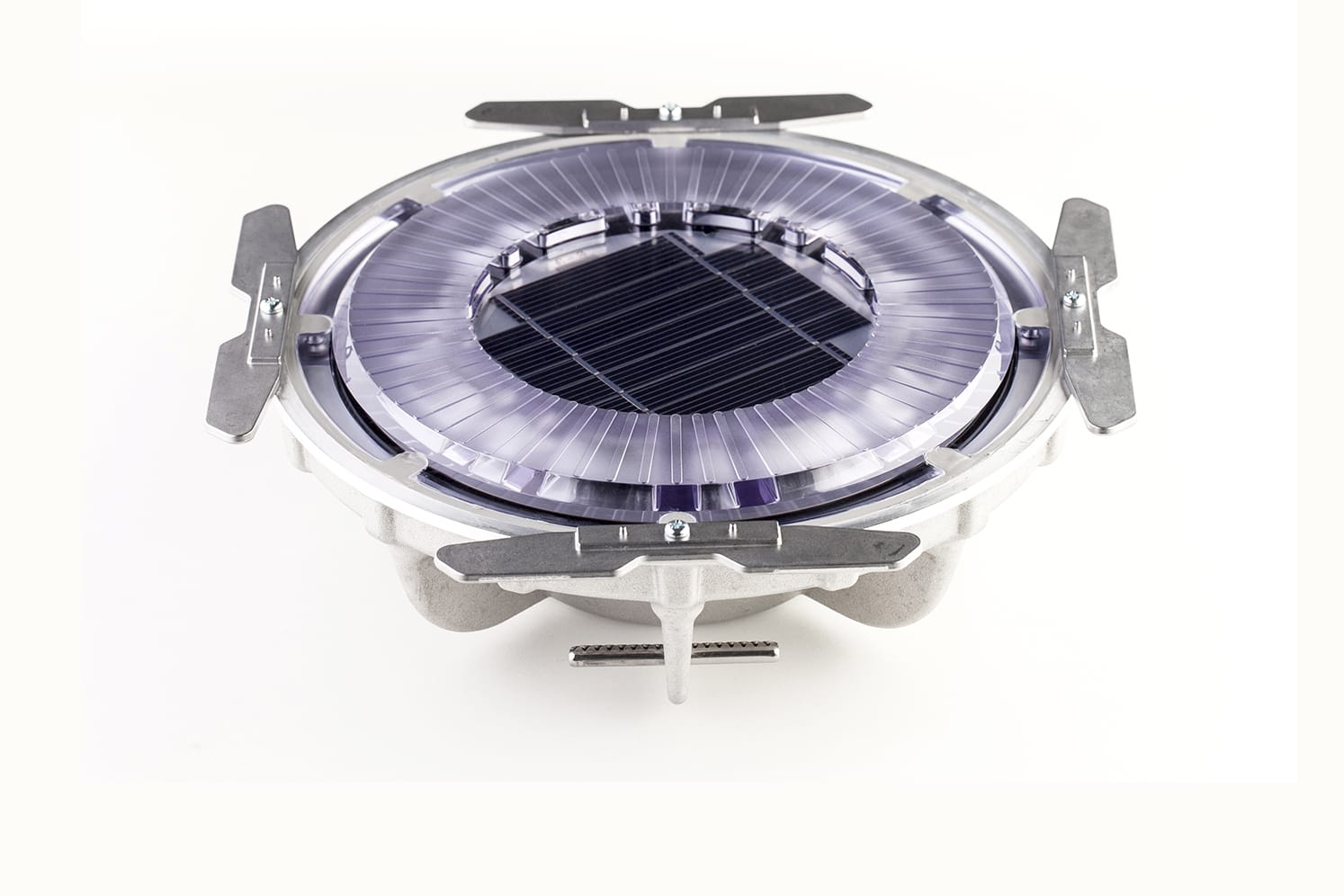

Upper diameter: 246 mm. Height: 83 mm.

Height above roadway: 5 mm.

Weight: approx. 2.7 kg.

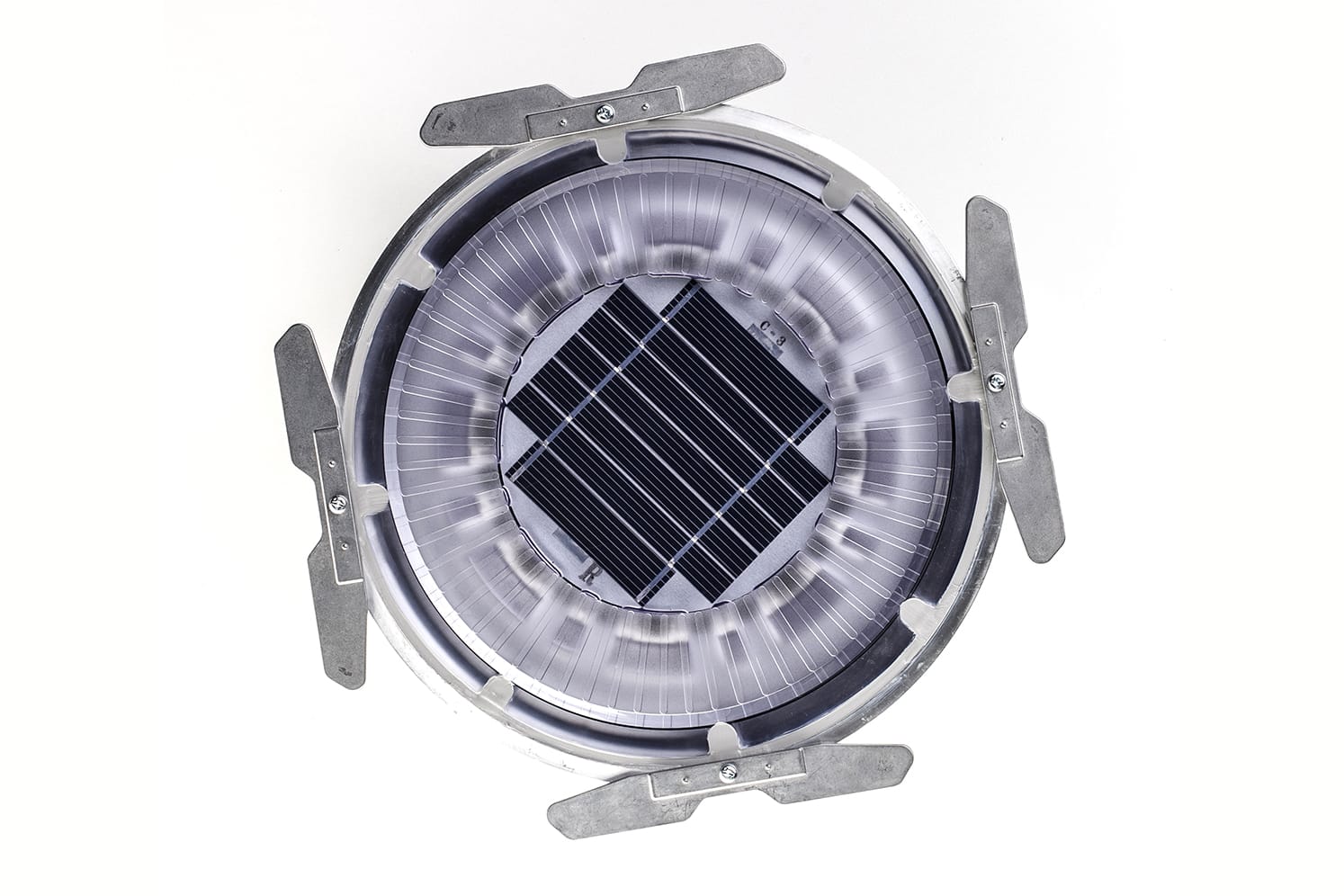

Screwed fins (removable) for easier installation supplied with the stud.

Materials

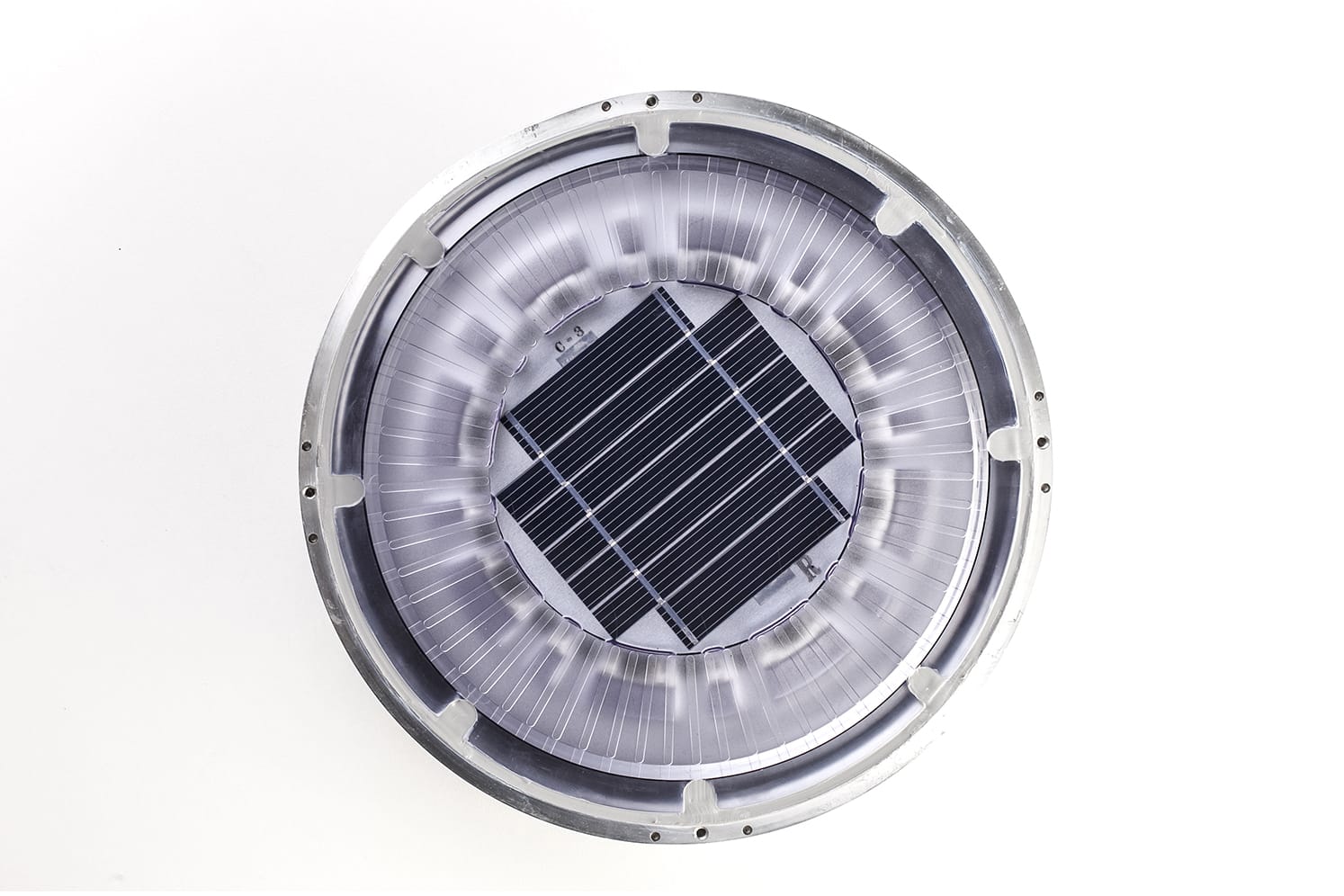

Aluminium, Polycarbonate, Silicon (photovoltaic panel).

Recycling managed by Recyclum.

Energy storage

Condenser.

Working temperature range

-30°C to +85°C

Protection indices

IP 68 (watertightness).

IK 10+ 100 Joules (impact resistance).

Pressure resistance

40 tonnes minimum (stud adapted to the repeated passage of 40t HGVs).

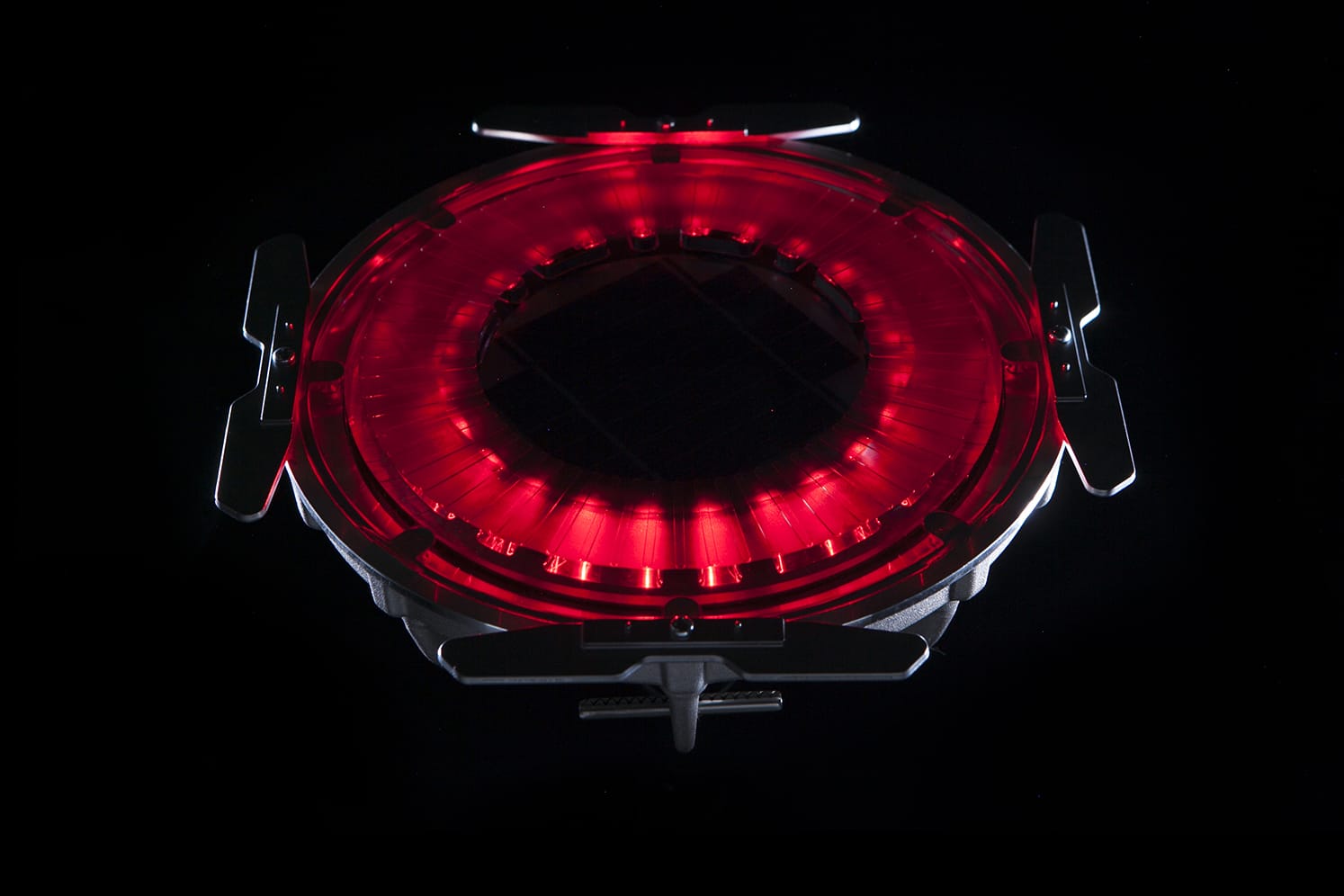

LIGHTING CHARACTERISTICS

LED colours: red.

Optics in front of LEDs to optimise light flow.

24 LED omnidirectional beaconing blinking in sequence, 2 programmes:

. 125 rpm (+/- 10%) during normal night-time operation,

. 325 rpm. (+/- 10%) for 15 seconds after detecting vehicle headlights.

1 – After deciding where the studs are to be installed, drill a hole with a minimum diameter of 254 mm and 100 mm deep.

2 – Carefully brush and clean the hole to remove any dust and traces of damp that would affect the efficiency of the adhesive.

3 – Pour the bonding adhesive or mortar into the hole to about 2/3 of the depth. We recommend using Sikadur 30 two part epoxy adhesive.

4 – Carefully press the stud into the adhesive. Remove any residual adhesive with a dry cloth and leave it to set for several hours depending on the ambient temperature (see the adhesive manufacturer’s instruments). Lastly, remove the plastic film protecting the solar module on the upper part of the stud. It is now ready for use.

Remarks

Make sure to keep the module and LEDs clean and protect them throughout these operations.

No product (mortar, glue, cleaner …) should be in contact with the upper part of the stud so as not to damage the aluminum and polycarbonate.

Failure to comply with these instructions may lead to the guarantee being suspended.

* The warranty applies in the event of complete failure of the self-contained lighting system during normal usage. It covers replacement of the faulty article with an identical model delivered free of charge to destinations in metropolitan France, after the faulty article has been returned and analysed. Removal of the faulty article, installation of the new one and any mechanical damage are not covered by the warranty.

ECO-INNOV is a founder member of a network that recycles professional WEEE, managed by the eco-organisation ECOSYSTEM. We pay for our customers’ electronic safety, lighting and regulation equipment to be collected at the end of its working life in order to meet our legal obligations and help them to meet theirs.

The unique identifier FR006801_05MBCK attesting to registration in the register of producers in the EEE sector, pursuant to article L.541-10-13 of the Environmental Code, has been assigned by ADEME to the company ECO- INNOV (SIRET 451 859 409 00026). This identifier certifies its conformity with regard to its obligation to registration in the register of producers of Electrical and Electronic Equipment and the realisation of its declarations of placing on the market with Ecosystem.

ECO-INNOV is thus one of the first producers to offer its customers a simple and free solution for collecting their professional WEEE, regardless of when it was marketed. The equipment is collected via a network of professional waste collection centres and certain wholesalers.